Brass Parts

Leading Manufacturers, Exporters and Wholesaler of Brass Auto Parts, Brass Casting Parts, Brass CNC Machined Parts, Brass Construction Parts, Brass Customized Parts, Brass Decorative Parts, Brass Electrical Parts, Brass Fastener Parts, Brass Fitting Parts, Brass Hardware Parts, Brass Lighting Parts, Brass Marine Engine Parts, Brass Medical Parts, Brass Meter Parts, Brass Miscellaneous Parts, Brass Sanitary Parts, Brass Smoking Pipe Parts and Stainless Steel 304 Grade Soft Close Cabinet Hinges from Jamnagar.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Size | Standard |

| Application | Auto Electrical Use |

| Color | Golden |

| Material | Brass |

| Surface Finishing | Polished |

Brass Auto Parts are meticulously engineered components designed to meet the rigorous demands of the automotive industry. Renowned for their durability, corrosion resistance, and excellent machinability, these parts are essential for enhancing the performance and longevity of various automotive systems. Manufactured using premium-grade brass, these components ensure precision, reliability, and optimal functionality in a wide range of applications.

Uses:

Brass Auto Parts are integral to numerous automotive systems, including but not limited to:

1. Fuel Systems: Brass fuel fittings and connectors provide a secure and leak-proof connection, ensuring efficient fuel flow and preventing leaks.

2. Cooling Systems: Brass radiator components and hose fittings offer superior thermal conductivity, aiding in effective heat dissipation and maintaining optimal engine temperature.

3. Brake Systems: Brass brake line fittings and valves ensure reliable hydraulic pressure management, contributing to safe and effective braking performance.

4. Electrical Systems: Brass terminals and connectors provide excellent electrical conductivity, ensuring stable and efficient power distribution.

5. Transmission Systems: Brass bushings and bearings reduce friction and wear, enhancing the smooth operation of transmission components.

Details:

Material Composition: High-quality brass alloy, typically comprising copper and zinc, with possible additions of other elements for enhanced properties.

Manufacturing Process: Precision machining, forging, and casting techniques are employed to create components with tight tolerances and intricate designs.

Surface Finish: Polished and treated surfaces to enhance corrosion resistance and aesthetic appeal.

Compatibility: Designed to meet OEM specifications and compatible with a wide range of automotive makes and models.

Customization: Availability of custom-designed parts to meet specific requirements and applications.

Benefits:

1. Durability: Brass components are known for their high strength and resistance to wear and tear, ensuring a long service life even under demanding conditions.

2. Corrosion Resistance: Brass is inherently resistant to corrosion, making it ideal for use in environments exposed to moisture, chemicals, and varying temperatures.

3. Machinability: Brass can be easily machined to precise specifications, allowing for the production of complex and detailed components.

4. Thermal Conductivity: Excellent heat dissipation properties make brass an ideal material for components exposed to high temperatures, such as in cooling systems.

5. Electrical Conductivity: Brass provides superior electrical conductivity, ensuring efficient power transmission and reliable performance in electrical applications.

6. Cost-Effectiveness: Despite its premium quality, brass offers a cost-effective solution due to its longevity and reduced maintenance requirements.

Brass Auto Parts represent a reliable and high-performance choice for various automotive applications. Their combination of durability, resistance to corrosion, excellent machinability, and superior conductivity makes them indispensable in ensuring the efficient and safe operation of modern vehicles. Whether you are looking to replace existing parts or seeking components for new automotive designs, Brass Auto Parts offer the quality and performance you need to keep your vehicles running smoothly and efficiently.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Brass |

| Surface Finishing | Polished |

| Color | Golden |

| Usage | Industrial |

| Size | Standard |

| Country of Origin | India |

Brass casting involves melting the alloy into a liquid form and pouring it into a mold. Once cooled and solidified, the brass takes the shape of the mold. This process allows for intricate designs and complex shapes, ideal for decorative hardware, doorknobs, and intricate plumbing components.

Benefits of Brass Casting:

- Design Freedom: Cast brass offers unmatched design flexibility. Even highly detailed shapes can be replicated with precision.

- Cost-Effective for Complex Parts: For intricate designs, casting is often more cost-effective than machining a solid piece of brass.

- Variety in Sizes: Castings can be produced in a wide range of sizes, from tiny decorative pieces to large industrial components.

Forging: Shaping Through Force

Brass forging involves heating the metal to a malleable state and then hammering or pressing it into the desired shape using dies. This process strengthens the grain structure of the metal, making it incredibly strong and resistant to pressure.

Benefits of Brass Forging:

- Superior Strength: Forged brass offers exceptional strength and durability, ideal for high-pressure applications like valves, gears, and pipe fittings.

- Improved Machinability: The denser grain structure of forged brass makes it easier to machine for precise finishes.

- Reduced Porosity: Forging eliminates internal air pockets, resulting in a denser, more leak-proof final product.

Choosing the Right Method:

The best method – casting or forging – depends on the desired properties of the final brass component.

- For intricate shapes and decorative elements, casting reigns supreme.

- For high-pressure applications requiring exceptional strength, forging is the clear choice.

The Power of Brass: A Material Tailored to Needs

Whether cast or forged, brass offers a unique blend of beauty and functionality. By understanding the strengths of each process, you can choose the perfect brass solution for your project.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Brass |

| Usage/Application | Industrial |

| Country of Origin | India |

| Surface | Polished |

| Size | Standard |

| Thickness | 5-10 mm |

CNC Machined Parts: Precision Solutions for Diverse Applications

Uses:

CNC Machined Parts find extensive applications across various industries:

- Automotive: Engine components, transmission parts, chassis, and suspension components.

- Aerospace: Aircraft structural components, landing gear parts, and engine components.

- Electronics: Enclosures, connectors, heatsinks, and PCB prototypes.

- Medical: Surgical instruments, implants, prosthetics, and medical device components.

- Industrial Machinery: Gears, shafts, valves, and housings for heavy-duty equipment.

- Consumer Goods: Customized parts for appliances, tools, and household products.

- Defense: Weapon components, armor parts, and military equipment.

- Energy: Turbine parts, generator components, and renewable energy equipment.

Details:

- Material Options: CNC Machined Parts can be fabricated from various materials including metals (aluminum, steel, titanium), plastics (ABS, acrylic, nylon), and composites.

- Precision Machining: Utilizes Computer Numerical Control (CNC) machines to achieve high precision and accuracy in the production of complex geometries and tight tolerances.

- Multi-axis Machining: Capable of multi-axis machining (3-axis, 4-axis, or 5-axis), allowing for intricate designs and complex shapes to be manufactured.

- Tooling: Employs a wide range of cutting tools such as end mills, drills, taps, and reamers to perform milling, turning, drilling, and other machining operations.

- Surface Finishing: Offers various surface finishes including anodizing, plating, painting, and powder coating to enhance aesthetics and provide additional properties such as corrosion resistance.

- Customization: CNC machining allows for customization of parts according to specific design requirements, including size, shape, features, and tolerances.

- Quality Control: Adheres to strict quality control measures throughout the machining process to ensure dimensional accuracy, surface finish, and overall quality of the machined parts.

Benefits:

- High Precision: CNC Machined Parts offer exceptional precision and accuracy, ensuring tight tolerances and consistent quality across production batches.

- Versatility: Capable of machining a wide range of materials, CNC machining provides versatility in design and material selection to meet diverse application needs.

- Complex Geometries: CNC machines can produce complex shapes and geometries that are difficult or impossible to achieve with conventional machining methods, enabling innovative designs.

- Efficiency: CNC machining is a highly efficient manufacturing process, allowing for rapid prototyping, short lead times, and cost-effective production of low to high-volume parts.

- Cost-Effectiveness: With reduced setup times and minimal material wastage, CNC machining offers cost-effective solutions for producing high-quality parts compared to traditional machining methods.

- Scalability: CNC machining is scalable, making it suitable for producing both prototype and production quantities of parts, providing flexibility in manufacturing volumes.

- Consistency: CNC machining ensures consistent quality and dimensional accuracy, minimizing variability and defects in the machined parts.

- Quality Assurance: CNC Machined Parts undergo rigorous quality control checks to verify dimensional accuracy, surface finish, and mechanical properties, ensuring reliability and performance.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Size | Standard |

| Color | Golden & Silver |

| Material | Brass |

| Finishing | Polished |

| Shape | Round |

Brass Construction Parts: Enhancing Durability and Aesthetics in Building Projects

Uses:

- Architectural Hardware: Utilized for door handles, hinges, knobs, and locks, adding a touch of elegance and functionality to architectural designs.

- Faucets and Fixtures: Incorporated into plumbing fixtures such as faucets, valves, and showerheads, providing corrosion resistance and longevity.

- Decorative Accents: Used for decorative trim, moldings, and accents on doors, windows, and cabinetry, enhancing the visual appeal of interior spaces.

- Lighting Fixtures: Employed in light fixtures, lamps, and chandeliers for their aesthetic appeal and corrosion resistance.

- Signage and Sign Holders: Utilized for signage, plaques, and sign holders in commercial and residential settings, offering durability and elegance.

- Staircase Components: Integral in staircase railings, balusters, and newel posts, enhancing safety and aesthetics in stairway designs.

- Curtain Hardware: Used for curtain rods, finials, and brackets, providing support and style to window treatments.

- Exterior Cladding: Incorporated into exterior cladding systems and façade elements, offering weather resistance and architectural detail.

Details:

- Material Composition: Brass construction parts are crafted from high-quality brass alloys, typically composed of copper and zinc, offering superior strength, corrosion resistance, and machinability.

- Finish Options: Available in various finishes including polished, satin, antique, and patina finishes, catering to different design preferences and architectural styles.

- Customization: Brass construction parts can be customized in terms of size, shape, and design to meet specific project requirements and design aesthetics.

- Attachment Methods: Offered with various attachment methods including screws, bolts, rivets, and adhesives, providing flexibility for installation and assembly.

- Quality Standards: Manufactured to meet or exceed industry standards and specifications, ensuring consistent quality and performance.

- Testing and Certification: Brass construction parts undergo testing and certification procedures to verify compliance with building codes and regulations.

Benefits:

- Durability: Brass construction parts offer exceptional durability and longevity, withstanding exposure to harsh weather conditions, moisture, and mechanical stress.

- Corrosion Resistance: Brass alloys are inherently resistant to corrosion, oxidation, and tarnishing, ensuring long-lasting performance in both indoor and outdoor applications.

- Aesthetic Appeal: The golden hue of brass adds a touch of elegance and sophistication to architectural designs, enhancing the overall aesthetic appeal of buildings and interiors.

- Versatility: Brass construction parts are versatile and adaptable, suitable for a wide range of architectural styles and design preferences.

- Low Maintenance: Brass requires minimal maintenance, with periodic cleaning sufficient to maintain its appearance and functionality.

- Environmental Sustainability: Brass is a recyclable material, supporting sustainability efforts and reducing environmental impact in building construction and renovation projects.

- Fire Resistance: Brass construction parts offer inherent fire resistance, contributing to the safety and integrity of building structures.

- Value Addition: Brass construction parts add value to buildings and properties, enhancing their marketability and resale potential.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Material | Brass |

| Color | Golden |

| Application | Industrial |

| Finishing | Polished |

| Size | Customized |

Customized Brass Parts: Tailored Precision for Diverse Applications

Uses:

Customized Brass Parts serve various industries:

- Automotive: Engine components, fuel systems, braking, and electrical connectors.

- Electronics: Terminals, connectors, casings, and shielding.

- Plumbing: Fittings, valves, couplings, ensuring reliability.

- Aerospace: Aircraft parts, hydraulic systems, instrumentation.

- Medical: Surgical instruments, implants, biocompatible equipment.

- Marine: Hardware, fittings, corrosion-resistant components.

- Industrial Machinery: Bearings, bushings, gears, heavy-duty fittings.

- Architectural: Decorative hardware, lighting, design elements.

Details:

- Material: High-quality brass alloys tailored for properties.

- Manufacturing: Precision machining, forging, casting.

- Customization: Size, shape, threading, finish, branding.

- Quality Standards: ASTM, DIN, ISO, BS compliant.

- Surface Finish: Natural, polished, plated, coated.

- Packaging: Flexible options for client preferences.

Benefits:

- Precision Engineering: Exact fit, form, function.

- Enhanced Performance: Strength, durability, conductivity.

- Cost Efficiency: Minimized waste, assembly time.

- Fast Turnaround: Rapid prototyping, reduced lead times.

- Versatility: Adaptable to diverse applications.

- Reliability: Consistent quality, minimal risks.

- Aesthetic Appeal: Custom finishes, visual enhancement.

- Sustainability: Recyclable, supports environmental goals.

Customized Brass Parts offer precise solutions across industries, ensuring functionality, reliability, aesthetics. Contact us for personalized service and high-quality solutions.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Size | Standard |

| Application | Industrial Use |

| Color | Golden,Silver |

| Material | Brass |

| Surface Finishing | Polished |

Elevate Your Space: The Enduring Beauty of Brass Decorative Parts

Brass decorative parts transcend mere function, transforming everyday objects into works of art. Crafted from a warm, golden alloy of copper and zinc, these pieces add a touch of sophistication and timeless elegance to furniture, cabinetry, and home décor.

Unwavering Beauty:

Unlike trendy finishes that fade with time, brass possesses an enduring appeal. Its natural luster can be polished to a gleaming shine or allowed to develop a rich patina for a more antique look. This versatility ensures your brass accents will complement any décor style, from classic to modern.

A World of Applications:

The creative possibilities with brass decorative parts are endless. Here are a few ways to incorporate them into your space:

- Furniture Accents: Elevate furniture pieces with decorative nailhead trim, casters, keyholes, and drawer pulls in brass.

- Cabinet Hardware: Replace plain knobs and pulls with ornate brass designs, instantly transforming the look of your cabinets.

- Door Hardware: Dress up doors with decorative hinges, handles, knockers, and kickplates in brass, creating a grand entrance.

- Lighting Fixtures: Brass lamp bases, sconces, and chandelier accents add a touch of warmth and sophistication to your lighting.

- Décorative Touches: From decorative hooks and cabinet keyholes to switch plates and fireplace surrounds, brass accents add a unique detail to any space.

Beyond Visual Appeal:

The benefits of brass decorative parts extend beyond their beauty:

- Durability: Brass is naturally resistant to rust, corrosion, and everyday wear and tear, ensuring your decorative accents will last for years to come.

- Low Maintenance: A simple wipe with a damp cloth keeps brass looking its best, requiring minimal upkeep.

- Increased Value: Brass accents add perceived value to your home, making them a worthwhile investment.

A Timeless Investment:

Brass decorative parts are more than just embellishments; they're an investment in the enduring quality and beauty of your home. Their versatility allows you to personalize your space and create a unique atmosphere. Whether you choose a polished gleam or a warm patina, brass adds a touch of timeless elegance that never goes out of style.

| Business Type | Manufacturer, Exporter, Supplier |

| Surface Finishing | Polished |

| Material | Brass |

| Color | Golden & Silver |

| Application | Industrial Use |

| Size | Standard |

| Country of Origin | India |

The Spark of Reliability: Brass Electrical Parts for Secure Connections

Brass plays a vital role behind the scenes in our electrical systems. Brass electrical parts, known for their durability and conductivity, ensure safe and efficient transfer of electricity throughout your home or business.

Strength that Conducts:

Unlike some alternative materials, brass offers superior electrical conductivity. This allows for efficient transfer of electricity with minimal resistance, minimizing power loss and ensuring your devices receive the current they need. More importantly, brass is incredibly strong and resistant to corrosion, preventing electrical breakdowns and potential fire hazards.

Safety First:

Electrical safety is paramount. Brass electrical parts contribute to a safer electrical environment thanks to their ability to withstand high temperatures often generated by electrical current. This reduces the risk of overheating and potential fires. Additionally, the tight connections offered by brass fittings minimize the chance of arcing, a dangerous spark that can occur with loose connections.

A Range of Applications:

Brass electrical parts come in a variety of configurations to suit diverse electrical needs. Here are some common examples:

- Terminals and Connectors: These parts securely connect wires to each other and to electrical components, ensuring a reliable flow of electricity.

- Switches and Outlets: The internal components of switches and outlets are often made from brass for their conductivity and durability.

- Fuse Components: Brass plays a crucial role in fuse boxes and circuit breakers, helping to safely interrupt electrical flow in case of overload.

- Grounding Components: Brass earth bars and grounding straps effectively channel excess current away from sensitive electronics, protecting them from damage.

Beyond the Basics:

The advantages of brass electrical parts go beyond just function:

- Fire Resistance: As mentioned earlier, brass's high melting point makes it a safer choice for electrical applications compared to materials prone to melting under high heat.

- Long-lasting Performance: Brass is resistant to corrosion, ensuring these parts function reliably for years to come.

- Easy Installation: Many brass electrical parts are designed for easy installation by qualified electricians.

Investing in Safety and Reliability:

While the upfront cost of brass electrical parts may be slightly higher than some alternatives, their superior conductivity, safety features, and longevity make them a worthwhile investment. They offer peace of mind knowing your electrical system functions safely and efficiently for years to come.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Brass |

| Surface Finishing | Polished |

| Color | Golden & Silver |

| Usage | Industrial |

| Certification | ISI Certified |

| Size | Standard |

| Country of Origin | India |

Brass Fasteners are premium-quality components designed to provide secure and reliable fastening solutions across various industries. Known for their exceptional durability, resistance to corrosion, and attractive appearance, these fasteners are ideal for applications requiring both strength and aesthetic appeal. Manufactured using high-grade brass, these fasteners are available in a wide range of types, sizes, and finishes to meet diverse industrial and commercial needs.

Uses:

Brass Fasteners are versatile and can be used in numerous applications, including:

1. Electronics and Electrical: Ideal for connecting components in electronic devices and electrical systems due to their excellent electrical conductivity.

2. Automotive: Used in vehicle assemblies for securing parts that require resistance to vibration and corrosion.

3. Construction: Suitable for architectural applications, plumbing fixtures, and decorative elements due to their strength and aesthetic appeal.

4. Marine: Perfect for marine applications where exposure to water and salt is common, thanks to their high corrosion resistance.

5. Industrial Machinery: Employed in machinery and equipment for secure and stable fastening in harsh environments.

6. DIY Projects: Popular in craft, hobby, and home improvement projects for their ease of use and appealing finish.

Details:

- Material Composition: Made from high-quality brass alloy (typically copper and zinc), ensuring robustness and longevity.

- Types: Available in various types, including screws, bolts, nuts, washers, rivets, and more.

- Sizes: Offered in a wide range of sizes to cater to different fastening needs.

- Finishes: Available in polished, natural, nickel-plated, and other finishes to enhance corrosion resistance and appearance.

- Standards: Manufactured to meet international standards such as ASTM, DIN, ISO, and BS, ensuring quality and compatibility.

- Packaging: Supplied in bulk or custom packaging as per client requirements.

Benefits:

1. Corrosion Resistance: Brass fasteners resist rust and corrosion, making them ideal for use in wet and humid environments.

2. Aesthetic Appeal: The natural golden sheen of brass adds a decorative element, making these fasteners perfect for visible installations.

3. Strength and Durability: Brass offers a good balance of strength and flexibility, ensuring reliable fastening without brittleness.

4. Electrical Conductivity: Excellent conductivity makes brass fasteners suitable for electrical and electronic applications.

5. Easy Machinability: Brass can be easily machined, allowing for precise and customized fastener production.

6. Non-Magnetic: Brass is non-magnetic, which is advantageous in applications where magnetic interference is a concern.

7. Recyclable: Brass is a sustainable material that can be recycled, contributing to environmental conservation efforts.

Brass Fasteners are an exceptional choice for a wide range of applications requiring reliable, durable, and aesthetically pleasing fastening solutions. Their unique properties make them suitable for use in harsh environments, delicate electronics, decorative constructions, and beyond. With a variety of types, sizes, and finishes available, Brass Fasteners from our collection ensure that you can find the perfect match for your specific needs, guaranteeing both performance and visual appeal.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Color | Golden |

| Finishing | Polished |

| Material | Brass |

| Application | Industrial |

| Size | Standard |

Brass Fitting Parts Keep Things Flowing

Behind the walls and under the sink lies a hidden world of components ensuring smooth operation in plumbing and gas systems: brass fitting parts. These workhorses, crafted from high-quality brass, are essential for connecting, controlling, and regulating the flow of liquids and gases.

Strength Where It Matters:

Unlike plastic fittings prone to cracking, brass fittings are built to last. Their robust nature makes them resistant to high pressure, extreme temperatures, and corrosion, ensuring reliable performance for years to come. This is crucial for applications like water supply lines and gas lines where leaks can have serious consequences.

Leak-Proof Performance:

Leaking connections are a homeowner's nightmare. Brass fittings, with their precision threading and tight tolerances, create secure connections that eliminate leaks. This saves water, gas, and the frustration of dealing with drips and puddles.

A Universe of Configurations:

Brass fitting parts come in a vast array of shapes and sizes, catering to virtually any plumbing or gas application. From simple couplers that connect pipes to complex multi-port manifolds, you'll find the perfect fitting to complete your project. Need to change direction in a pipe run? Use an elbow. Branching off to a new line? A tee fitting is the answer. Adapters allow for connecting pipes of different diameters, ensuring compatibility in any system.

Beyond Durability:

The benefits of brass fitting parts extend beyond their strength and leak-proof nature:

- Easy Installation: Most brass fittings require just basic tools for installation, making them DIY-friendly for even the novice homeowner.

- Investment Grade: While the initial cost might be slightly higher than plastic options, brass fittings are a long-term investment. Their durability eliminates the need for frequent replacements, saving you money in the long run.

- Fire Safety: Brass is a non-combustible material, providing an added layer of safety in gas line applications.

The Foundation of Reliable Systems:

Whether you're a professional plumber or a homeowner tackling a DIY project, brass fitting parts are the unsung heroes that ensure your plumbing and gas systems function smoothly and safely. Their strength, leak-proof performance, and versatility make them the ideal choice for any application.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Size | Standard |

| Application | Industrial Use |

| Color | Golden & Silver |

| Material | Brass |

| Surface Finishing | Polished |

Timeless Appeal: The Versatility of Brass Hardware Parts

Brass hardware parts transcend mere function, adding a touch of elegance and durability to cabinets, furniture, doors, and more. Crafted from a copper-zinc alloy, brass offers a unique combination of beauty and strength, making it a popular choice for both residential and commercial applications.

Unmatched Durability:

Unlike its plastic counterparts, brass hardware is built to endure. It's resistant to rust, corrosion, and everyday wear and tear, ensuring years of smooth operation. High-traffic areas like kitchens and bathrooms pose no challenge for these sturdy components.

Functional Elegance:

The warm, golden hue of brass adds a touch of sophistication to any space. Available in a variety of finishes – from polished brass to antique bronze – you can find the perfect match to complement your existing décor.

Extensive Applications:

The versatility of brass hardware is unmatched. Here are just a few examples of its many uses:

- Door Hardware: Door hinges, knobs, handles, knockers, and kickplates in brass create a lasting impression.

- Cabinet Hardware: Drawer pulls, knobs, and hinges in brass elevate the look of your kitchen or bathroom cabinets.

- Furniture Accents: Brass accents like casters, nailhead trim, and decorative brackets add a touch of class to furniture pieces.

- Window Hardware: Window latches, stays, and sash lifts in brass provide a classic touch to your windows.

- Decorative Accents: From decorative hooks and cabinet keyholes to switch plates and fireplace surrounds, brass adds a unique detail to any space.

Benefits Beyond Aesthetics:

The advantages of brass hardware extend far beyond its visual appeal:

- Smooth Operation: The inherent sturdiness of brass ensures hardware operates smoothly for years to come, free of sticking or jamming.

- Easy Maintenance: Brass requires minimal upkeep. A simple wipe with a damp cloth keeps its shine for years.

- Increased Value: Brass hardware adds perceived value to your home, making it a worthwhile investment.

Investing in Quality:

Brass hardware may have a slightly higher initial cost than plastic options, but its durability and timeless appeal make it a cost-effective choice in the long run. You'll eliminate the need for frequent replacements, saving you money over time.

A Touch of History:

For centuries, brass has been a preferred material for hardware. Its rich history and enduring appeal ensure it will continue to be a popular choice for homeowners and designers alike. By incorporating brass hardware into your space, you're not just adding functionality, you're adding a touch of timeless elegance that will never go out of style.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| CNC Machining or Not | Yes |

| Size | Standard |

| Application | Industrial Use |

| Color | Golden & Silver |

| Material | Brass |

| Surface Finishing | Polished |

Brass Lighting Parts: Enhancing Illumination with Durability and Elegance

Uses:

Brass lighting parts serve as essential components in various lighting fixtures, enhancing illumination and aesthetics in indoor and outdoor settings:

- Chandeliers: Utilized in chandeliers for their elegance and ability to support multiple light sources.

- Lamps: Integral in lamp fixtures including table lamps, floor lamps, and desk lamps, providing stability and style.

- Wall Sconces: Employed in wall-mounted sconces to support and secure light fixtures against vertical surfaces.

- Ceiling Fixtures: Used in ceiling-mounted fixtures such as pendant lights, flush mounts, and semi-flush mounts, offering durability and visual appeal.

- Outdoor Lighting: Utilized in outdoor lighting fixtures including wall lanterns, post lights, and pathway lights, providing weather resistance and longevity.

- Track Lighting: Integral components in track lighting systems for directional and adjustable illumination in commercial and residential spaces.

- Lamp Shades: Incorporated in lamp shades and light diffusers to support and secure the light source while adding decorative elements.

- Custom Lighting: Adapted for custom lighting designs and installations, allowing for creativity and personalization in lighting projects.

Details:

- Material Composition: Brass lighting parts are crafted from high-quality brass alloys, typically composed of copper and zinc, offering strength, corrosion resistance, and machinability.

- Design: Designed with precision engineering to ensure compatibility with various lighting fixtures and to enhance their aesthetics.

- Surface Finish: Finished with polishing, plating, or coating processes to enhance corrosion resistance, durability, and aesthetic appeal.

- Size and Dimensions: Available in various sizes and dimensions to fit different lighting fixtures and accommodate different bulb types.

- Attachment Methods: Equipped with mounting holes, threaded inserts, or other attachment features to facilitate easy installation and secure attachment to light fixtures.

- Quality Standards: Manufactured to meet or exceed industry standards and specifications, ensuring reliable performance and safety.

Benefits:

- Durability: Brass lighting parts offer exceptional durability and longevity, withstanding exposure to heat, moisture, and environmental elements.

- Corrosion Resistance: Brass alloys are inherently resistant to corrosion and oxidation, ensuring long-lasting performance in indoor and outdoor lighting applications.

- Stability: Brass lighting parts provide stability and support to light fixtures, preventing wobbling or shifting during installation or use.

- Aesthetic Appeal: The golden hue of brass adds a touch of elegance and sophistication to lighting fixtures, enhancing the overall visual appeal of interior and exterior spaces.

- Versatility: Brass lighting parts are versatile and adaptable, suitable for a wide range of lighting styles and designs, from traditional to contemporary.

- Ease of Installation: Designed for easy installation with standard tools, allowing for quick and hassle-free assembly of lighting fixtures.

- Customization: Brass lighting parts can be customized in terms of size, shape, and finish to meet specific design requirements and preferences.

- Environmental Sustainability: Brass is a recyclable material, supporting sustainability efforts and reducing environmental impact in lighting manufacturing and disposal processes.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Brass |

| Finishing | Polished |

| Color | Golden |

| Application | Marine Engine |

| Size | Standard |

| Country of Origin | India |

Uses:

- Boat Hardware: Used in the manufacturing of boat hardware such as cleats, hinges, handles, and navigation lights, providing strength and corrosion resistance.

- Engine Components: Integral in marine engine components including pumps, valves, fittings, and heat exchangers, ensuring efficient performance and longevity.

- Propulsion Systems: Employed in propulsion systems such as propellers, shafts, and couplings, providing durability and resistance to corrosion and marine growth.

- Steering Systems: Components in steering systems including rudder fittings, steering wheels, and control levers, ensuring precise and reliable maneuverability.

- Deck Fittings: Utilized in deck fittings such as bollards, fairleads, and railings, providing secure mooring and safety on board.

- Electrical Components: Used in electrical systems including connectors, terminals, and switches, providing conductivity and corrosion resistance.

- Plumbing Systems: Integral in plumbing systems including through-hull fittings, valves, and hose fittings, ensuring leak-proof connections and efficient water distribution.

- Anchoring Systems: Components in anchoring systems including anchor rollers, chains, and swivels, ensuring secure anchorage and stability.

Details:

- Material Composition: Brass marine parts are crafted from high-quality brass alloys, typically composed of copper and zinc, offering excellent corrosion resistance, strength, and durability in marine environments.

- Surface Finish: Finished with polishing, plating, or coating processes to enhance corrosion resistance and aesthetic appeal, ensuring longevity and performance in marine applications.

- Design: Designed with marine-specific features such as corrosion-resistant materials, reinforced structures, and watertight seals to withstand the challenges of marine environments.

- Customization: Available in various sizes, shapes, and designs to meet specific requirements of different marine applications and vessels.

- Quality Standards: Manufactured to meet or exceed marine industry standards and specifications, ensuring reliability, safety, and compliance with regulations.

Benefits:

- Corrosion Resistance: Brass marine parts offer exceptional resistance to corrosion, oxidation, and saltwater exposure, ensuring long-lasting performance and durability in marine environments.

- Strength: Brass alloys provide high tensile strength and durability, capable of withstanding mechanical stress, vibration, and impact common in marine applications.

- Durability: Brass marine parts are highly durable and resistant to wear and tear, ensuring reliable performance and longevity even in harsh marine conditions.

- Low Maintenance: Brass parts require minimal maintenance, with periodic cleaning sufficient to maintain their appearance and functionality, reducing maintenance costs and downtime.

- Conductivity: Brass offers good electrical conductivity, making it suitable for electrical components and systems in marine vessels.

- Aesthetic Appeal: The golden hue of brass adds aesthetic value to marine vessels, enhancing their overall appearance and visual appeal.

- Versatility: Brass marine parts are versatile and adaptable, suitable for a wide range of marine applications and vessels, providing flexibility and compatibility with different systems and components.

- Environmental Sustainability: Brass is a recyclable material, supporting sustainability efforts and reducing environmental impact in marine construction and operations.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Brass |

| Finishing | Polished |

| Color | Golden & Silver |

| Size | Standard |

| Country of Origin | India |

| Application | Industrial Use |

Brass Medical Parts: Precision Components for Medical Devices and Equipment

Uses:

Brass medical parts play a critical role in the functionality and reliability of various medical devices and equipment:

- Surgical Instruments: Utilized in the manufacturing of surgical instruments, providing strength, precision, and durability.

- Diagnostic Equipment: Essential components in diagnostic devices such as X-ray machines, MRI scanners, and blood analyzers.

- Dental Tools: Employed in dental tools and equipment for their corrosion resistance and biocompatibility.

- Implant Devices: Used in certain types of implants and prosthetics, ensuring biocompatibility and durability.

- Respiratory Equipment: Integral parts in respiratory devices such as ventilators and oxygen concentrators, ensuring reliable performance.

- Monitoring Devices: Used in patient monitoring systems, including blood pressure monitors and ECG machines.

- Infusion Systems: Components in infusion pumps and IV therapy equipment, providing precise and reliable fluid control.

- Laboratory Equipment: Employed in laboratory instruments and devices for their precision and resistance to chemical corrosion.

Details:

- Material Composition: Brass medical parts are crafted from high-quality brass alloys, typically composed of copper and zinc, offering a balance of strength, corrosion resistance, and machinability.

- Precision Engineering: Manufactured using advanced precision engineering techniques to meet the stringent requirements of medical applications.

- Surface Finish: Features various surface finishes such as polished, electroplated, or coated to enhance corrosion resistance and biocompatibility.

- Customization: Available in a range of sizes, shapes, and designs to meet specific requirements of different medical devices and equipment.

- Compliance: Manufactured in compliance with medical industry standards and regulations, ensuring safety and reliability.

- Quality Control: Undergo rigorous quality control procedures, including testing for dimensional accuracy, strength, and surface integrity.

Benefits:

- Durability: Brass medical parts offer exceptional durability, withstanding repeated use, sterilization, and exposure to harsh environments.

- Corrosion Resistance: Brass alloys are inherently resistant to corrosion and oxidation, ensuring long-lasting performance in medical applications.

- Precision: Precision-engineered brass parts ensure accurate and reliable operation of medical devices and equipment.

- Biocompatibility: Brass components are biocompatible, making them suitable for use in medical devices that come into contact with bodily fluids and tissues.

- Thermal Conductivity: Brass offers good thermal conductivity, which is beneficial for devices that require temperature regulation or dissipation.

- Versatility: Brass medical parts are versatile and adaptable, suitable for a wide range of medical applications and devices.

- Ease of Sterilization: Brass components can be easily sterilized using standard medical sterilization methods, ensuring hygiene and safety.

- Environmental Sustainability: Brass is a recyclable material, supporting sustainability efforts and reducing environmental impact in the medical industry.

- Aesthetic Appeal: The smooth finish and golden hue of brass add aesthetic value to medical devices and instruments, enhancing their overall appearance.

- Cost-Effectiveness: Brass medical parts provide a cost-effective solution, offering a balance of performance, durability, and affordability.

| Business Type | Manufacturer, Exporter, Supplier |

| Size | Standard |

| Application | Industrial |

| Color | Golden |

| Material | Brass |

| Surface Finishing | Polished |

| Country of Origin | India |

Uses:

- Water Meters: Used in residential, commercial, and industrial water meters to measure water consumption accurately.

- Gas Meters: Integral components in gas meters for monitoring and recording gas usage.

- Electric Meters: Employed in electric meters to ensure precise measurement of electricity consumption.

- Flow Meters: Used in flow meters to measure the flow rate of liquids and gases in pipelines and processing systems.

- Pressure Gauges: Incorporated in pressure gauges to monitor and measure pressure in various systems.

- Heat Meters: Essential in heat meters for measuring thermal energy consumption in heating systems.

- Fuel Meters: Utilized in fuel meters for accurate measurement of fuel usage in vehicles and machinery.

- Custom Measurement Systems: Adapted for specialized and custom measurement systems in various industries.

Details:

- Material Composition: Brass meter parts are crafted from high-quality brass alloys, typically composed of copper and zinc, offering superior strength, corrosion resistance, and durability.

- Types of Parts: Include components such as gears, connectors, housings, couplings, valves, and fittings, each designed to ensure accurate measurement and reliable operation.

- Precision Engineering: Manufactured with precision engineering techniques to ensure tight tolerances, consistent quality, and reliable performance.

- Size and Dimensions: Available in a range of sizes and dimensions to fit different types of meters and measurement devices.

- Surface Finish: Finished with polishing, plating, or coating processes to enhance corrosion resistance, durability, and aesthetic appeal.

- Quality Standards: Manufactured to meet or exceed industry standards and specifications, ensuring consistent quality and performance.

- Testing and Certification: Brass meter parts undergo rigorous testing and certification procedures to verify accuracy, durability, and compliance with relevant standards and regulations.

Benefits:

- Durability: Brass meter parts offer exceptional durability and longevity, withstanding exposure to harsh environments, moisture, and mechanical stress.

- Corrosion Resistance: Brass alloys are inherently resistant to corrosion, oxidation, and tarnishing, ensuring long-lasting performance in various applications.

- Precision: Precision-engineered brass meter parts ensure accurate measurement and reliable performance in all types of meters.

- Versatility: Brass meter parts are versatile and adaptable, suitable for a wide range of measurement applications across different industries.

- Ease of Maintenance: Brass components require minimal maintenance, with periodic cleaning sufficient to maintain their accuracy and functionality.

- Environmental Sustainability: Brass is a recyclable material, supporting sustainability efforts and reducing environmental impact in manufacturing and usage.

- Conductivity: Brass offers good electrical and thermal conductivity, making it ideal for use in electric and heat meters.

- Cost-Effectiveness: Brass meter parts provide a cost-effective solution, offering a balance of performance, durability, and affordability.

- Temperature Resistance: Brass parts can withstand a wide range of temperatures, ensuring reliable performance in various environmental conditions.

- Aesthetic Appeal: The golden hue of brass adds a touch of elegance and sophistication to meter components, enhancing the overall aesthetic appeal.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Size | Standard |

| Application | Industrial Use |

| Color | Golden & Silver |

| Material | Brass |

| Surface Finishing | Polished |

Brass Miscellaneous Parts are versatile components designed for a wide range of applications, offering exceptional performance and reliability. These parts are manufactured from high-quality brass, a material known for its strength, durability, and excellent resistance to corrosion. With precision engineering and a variety of types, sizes, and specifications, Brass Miscellaneous Parts are essential in numerous industries, including automotive, electrical, plumbing, and more.

Uses:

Brass Miscellaneous Parts find applications in several sectors:

- Automotive Industry: Utilized in fuel systems, brake systems, and cooling systems for secure and reliable connections.

- Electrical and Electronics: Ideal for connectors, terminals, and switch components due to excellent electrical conductivity.

- Plumbing: Used in fittings, valves, and fixtures for leak-proof and corrosion-resistant connections.

- Construction: Employed in architectural hardware and decorative elements for their aesthetic appeal and strength.

- Marine Applications: Suitable for components exposed to saltwater, ensuring longevity and corrosion resistance.

- Industrial Machinery: Integral in various machine components for their wear resistance and durability.

- DIY Projects: Popular for custom and hobby projects due to ease of machining and attractive finish.

Details:

- Material Composition: Made from high-quality brass alloy, typically composed of copper and zinc, with possible additions of other elements for enhanced properties.

- Manufacturing Process: Precision casting, forging, and machining techniques ensure tight tolerances and high-quality finishes.

- Types: Includes a variety of components such as bushings, spacers, connectors, fittings, valves, washers, and custom parts.

- Sizes: Available in a wide range of standard and custom sizes to meet diverse application needs.

- Standards: Manufactured to meet international standards such as ASTM, DIN, ISO, and BS, ensuring compatibility and reliability.

- Finish: Available in polished, natural, nickel-plated, and other finishes to enhance corrosion resistance and aesthetic appeal.

- Customization: Custom-designed parts are available to meet specific requirements and applications.

Benefits:

- Corrosion Resistance: Brass offers superior resistance to rust and corrosion, making it ideal for use in wet and humid environments.

- Durability: High strength and wear resistance ensure long-lasting performance, even in demanding conditions.

- Machinability: Brass is easily machinable, allowing for precise and intricate designs.

- Electrical Conductivity: Excellent conductivity makes brass ideal for electrical and electronic applications, ensuring stable and efficient power distribution.

- Thermal Conductivity: Brass's ability to effectively dissipate heat makes it suitable for components exposed to high temperatures.

- Aesthetic Appeal: The natural golden sheen of brass adds a decorative element, making it perfect for visible installations and architectural applications.

- Versatility: A wide range of types, sizes, and custom options makes brass parts suitable for diverse applications across various industries.

- Non-Magnetic: Brass is non-magnetic, which is advantageous in applications where magnetic interference is a concern.

- Eco-Friendly: Brass is a recyclable material, contributing to sustainability and environmental conservation.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Size | Standard |

| Application | Sanitary Use |

| Color | Golden & Silver |

| Surface Finishing | Polished |

| Material | Brass |

Brass Sanitary Parts: Elevating Hygiene and Durability in Plumbing

Uses:

Brass sanitary parts play a crucial role in plumbing systems, ensuring hygiene, durability, and reliability:

- Faucets and Valves: Essential components in faucets, taps, and valves, providing precise control over water flow and temperature.

- Pipe Fittings: Connectors, elbows, tees, and adapters used to join and redirect pipes in plumbing installations.

- Shower Heads and Sprayers: Components in shower systems, providing efficient water distribution and adjustable spray patterns.

- Drains and Traps: Designed to prevent the passage of debris and foul odors, maintaining cleanliness and sanitation.

- Flush Valves and Handles: Found in toilets and urinals, facilitating flushing action and water control.

- Bidet Attachments: Components in bidet systems, offering hygiene and comfort in personal cleansing.

- Fixture Mountings: Mounting brackets, clamps, and supports for securing fixtures such as sinks, toilets, and bathtubs.

- Accessories: Decorative elements like knobs, handles, and trim pieces, enhancing the aesthetic appeal of sanitary fixtures.

Details:

- Material Composition: Brass sanitary parts are crafted from high-quality brass alloys, known for their corrosion resistance, antimicrobial properties, and machinability.

- Precision Manufacturing: Utilizes advanced machining techniques, including CNC (Computer Numerical Control) machining, to ensure precise dimensions and tight tolerances.

- Surface Finishes: Finished with polishing, plating, or coating processes to enhance aesthetics, corrosion resistance, and ease of cleaning.

- Thread Types: Standardized thread types such as NPT (National Pipe Thread) or BSP (British Standard Pipe) ensure compatibility with existing plumbing systems.

- Sealing Mechanisms: Incorporates rubber seals, O-rings, and gaskets to create watertight connections and prevent leaks.

- Quality Assurance: Rigorous testing and inspection procedures ensure that each brass sanitary part meets industry standards for performance, durability, and safety.

- Environmental Considerations: Brass alloys are recyclable and environmentally friendly, supporting sustainability initiatives in the plumbing industry.

Benefits:

- Corrosion Resistance: Brass alloys offer excellent resistance to corrosion and rust, ensuring long-lasting performance in wet environments.

- Hygiene: Antimicrobial properties inherent in brass alloys help inhibit the growth of bacteria and fungi, promoting cleanliness and sanitation.

- Durability: Brass sanitary parts are durable and resilient, capable of withstanding frequent use, temperature fluctuations, and chemical exposure.

- Ease of Installation: Standardized dimensions and thread types ensure easy installation and compatibility with existing plumbing fixtures and systems.

- Aesthetic Appeal: The lustrous golden hue of brass adds a touch of elegance and sophistication to sanitary fixtures, enhancing the overall aesthetic of bathrooms and kitchens.

- Low Maintenance: Brass sanitary parts require minimal maintenance, with periodic cleaning sufficient to maintain their appearance and functionality.

- Reliability: Well-crafted brass sanitary parts offer reliable performance, minimizing the risk of leaks, malfunctions, and costly repairs.

- Versatility: Brass alloys can be machined into a wide range of shapes and configurations, offering versatility in design and application.

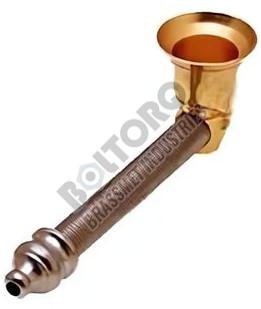

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Brass |

| Finishing | Polished |

| Color | Golden & Silver |

| Application | Smoking Pipes |

| Size | Standard |

| Country of Origin | India |

Brass Smoking Parts: Enhancing Your Smoking Experience

Uses:

- Pipe Fittings: Used in pipe construction, including bowls, stems, and mouthpieces, for their heat resistance and corrosion resistance.

- Lighter Components: Integral parts of lighters, such as flint wheels, spark wheels, and fuel caps, ensuring reliable ignition and durability.

- Grinders and Crushers: Components in herb grinders and crushers, including teeth, chambers, and screens, facilitating efficient grinding and filtering.

- Accessories: Decorative elements such as knobs, handles, and trim pieces, enhancing the aesthetic appeal of smoking devices.

- Valves and Connectors: Found in smoking devices with adjustable airflow or multiple chambers, providing control and versatility.

- Filters and Screens: Essential for filtering smoke and trapping ash, enhancing the purity and smoothness of the smoking experience.

- Ashtray Components: Components in ashtrays, such as trays, lids, and handles, offering convenience and durability for ash disposal.

- Customized Parts: Tailored components for specialty smoking devices, catering to individual preferences and requirements.

Details:

- Material Composition: Brass smoking parts are crafted from high-quality brass alloys, known for their heat resistance, corrosion resistance, and aesthetic appeal.

- Precision Machining: Utilizes advanced CNC (Computer Numerical Control) machining techniques to achieve intricate designs, tight tolerances, and smooth finishes.

- Surface Treatment: Finished with polishing, plating, or coating processes to enhance durability, resistance to tarnishing, and visual appeal.

- Customization Options: Brass smoking parts can be customized in terms of size, shape, surface finish, and engraving, offering personalized smoking experiences.

- Safety Features: Manufactured with attention to detail and quality control measures to ensure compliance with safety standards and regulations.

- Compatibility: Designed to fit seamlessly with existing smoking devices, ensuring compatibility and ease of integration.

- Ergonomic Design: Consideration of user comfort and usability in the design of smoking parts, promoting an enjoyable and ergonomic smoking experience.

- Environmentally Friendly: Brass alloys are recyclable and environmentally friendly, supporting sustainability efforts in the smoking industry.

Benefits:

- Enhanced Durability: Brass smoking parts offer durability and longevity, withstanding frequent use and handling without deterioration.

- Heat Resistance: Brass alloys can withstand high temperatures without deforming or corroding, ensuring safety and reliability during smoking sessions.

- Corrosion Resistance: Brass alloys are resistant to corrosion and tarnishing, maintaining their appearance and functionality over time.

- Aesthetic Appeal: The lustrous golden hue of brass adds a touch of elegance and sophistication to smoking devices, enhancing their visual appeal.

- Smooth Performance: Precision machining ensures smooth surfaces and tight tolerances, promoting smooth airflow and efficient operation.

- Customization Possibilities: Customized brass smoking parts allow users to personalize their smoking devices, reflecting individual style and preferences.

- Safety Assurance: Quality craftsmanship and compliance with safety standards ensure safe and enjoyable smoking experiences for users.

- Convenience: Well-designed smoking parts offer convenience and ease of use, enhancing the overall smoking experience for enthusiasts.

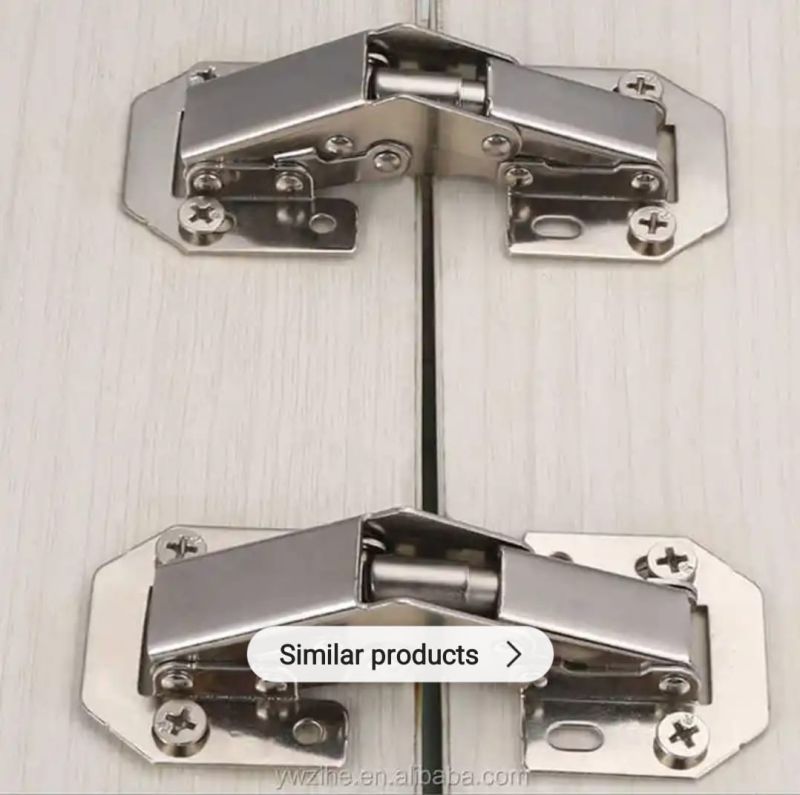

| Business Type | Manufacturer |

| Brand Name | BOLTORQ BRASSMET INDUSTRIES |

| Material | Stainless Steel |

| Application | SMOOTH AUTO CLOSE DOOR |

| Feature | Durable, Rust Proof,Perfect Strength,Fine Finished |

| Color | NICKED |

| Length | 4inch, 3inch |

| Width | 50-100mm |

| Packaging Size | <10 Piece, 10 - 20 Pieces, 50 - 100 Pieces, > 100 Pieces |

| Port | INDIA |

| Payment Terms | Other |

| Delivery Time | 2 WORKING WEEKS |

| Packaging Details | INDIVIDUAL PACKING , ONE BIGGER CARTOON CONTAINS 100 PACKET |

PRODUCT NAME: SOFT CLOSE BUFFER CABINET HINGES

MATERIALS: COLLED ROLLED STEEL

COLOR: NICKEL

SURFACE FINISH: NICKED

DOOR THICKNESS: 14-20MM

OPENING ANGLE: 95 DEGREE

DIAMETER OF HINGE CUP: 35 MM

WEIGHT: 80 GRAM

MOQ:1000